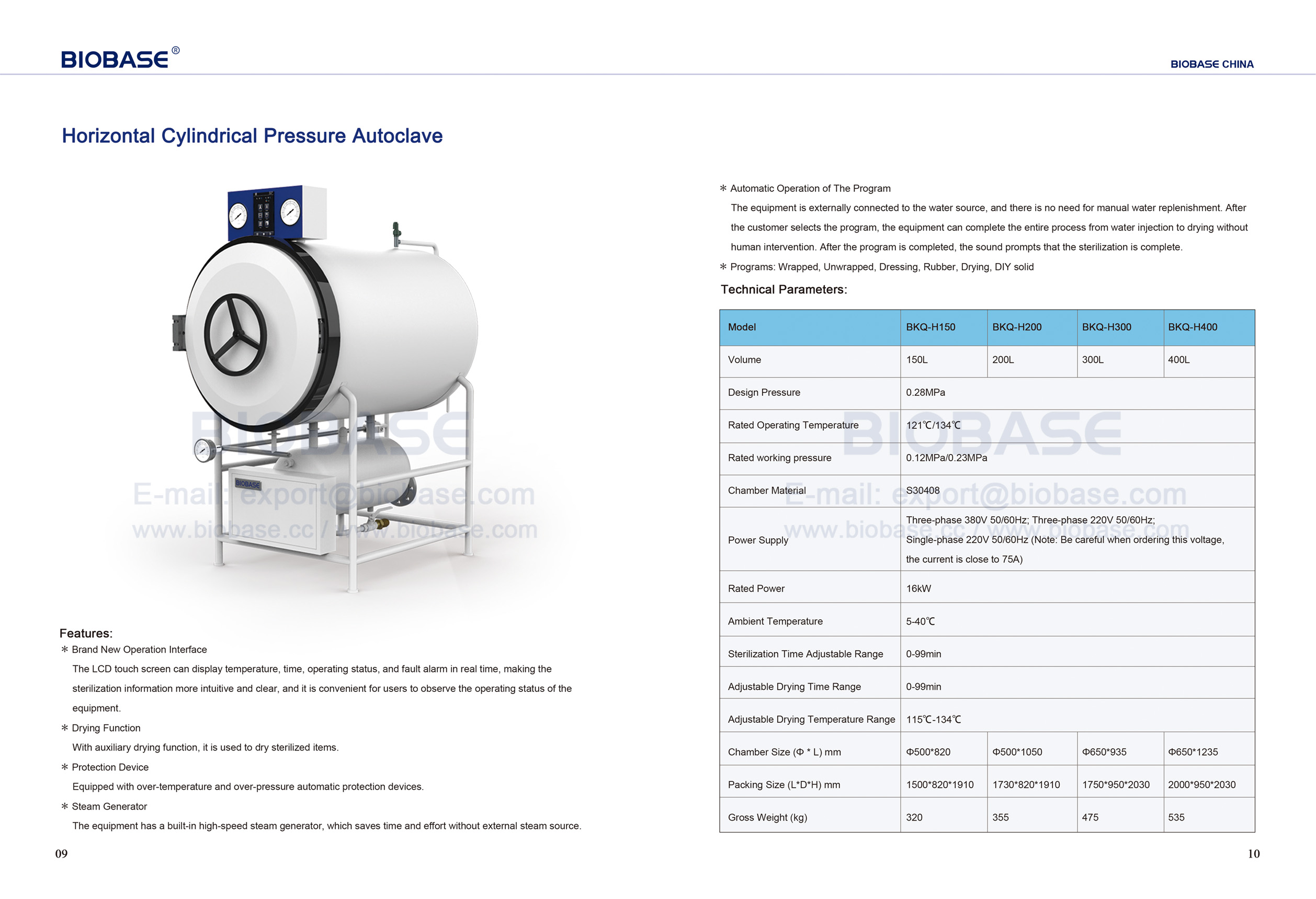

Safety Devices On Cylindrical Horizontal Autoclaves

Cylindrical horizontal autoclaves are a type of pressure vessel used for sterilization and other high-pressure applications. These vessels are designed to withstand extreme conditions, but they can be hazardous if not equipped with proper safety devices. In this article, we will discuss the importance of safety devices on cylindrical horizontal autoclaves and the various types of devices used to ensure safe operation.

Introduction to Autoclave Safety

Autoclaves are pressurized vessels that use high temperatures and pressures to achieve sterilization. Cylindrical horizontal autoclaves are commonly used in laboratories, hospitals, and industrial settings. However, the high pressures and temperatures involved in autoclave operation pose significant risks to personnel and equipment. Safety devices are essential to mitigate these risks and ensure safe operation. Pressure vessels, like autoclaves, are subject to stringent safety regulations and guidelines, such as those outlined by the American Society of Mechanical Engineers (ASME).

Safety Device Categories

Safety devices on cylindrical horizontal autoclaves can be categorized into several types, including:

- Pressure relief devices: These devices are designed to release excess pressure in the event of an overpressure situation.

- Temperature control devices: These devices monitor and control the temperature of the autoclave to prevent overheating or underheating.

- Interlock devices: These devices prevent the autoclave from operating under certain conditions, such as when the door is not properly closed or when the pressure is not within a safe range.

- Alarm and warning systems: These systems alert personnel to potential hazards, such as high pressure or temperature, or malfunctioning safety devices.

| Safety Device | Description |

|---|---|

| Pressure relief valve | Releases excess pressure to prevent vessel rupture |

| Temperature sensor | Monitors temperature to prevent overheating or underheating |

| Door interlock | Prevents autoclave operation when door is not properly closed |

| Alarm horn | Alerts personnel to potential hazards, such as high pressure or temperature |

Specific Safety Devices and Their Functions

In this section, we will discuss specific safety devices used on cylindrical horizontal autoclaves and their functions.

Pressure Relief Devices

Pressure relief devices are designed to release excess pressure in the event of an overpressure situation. These devices include:

Pressure relief valves: These valves are designed to open when the pressure in the autoclave exceeds a predetermined limit, releasing excess pressure and preventing vessel rupture. Spring-loaded pressure relief valves are commonly used in autoclaves.

Rupture discs: These discs are designed to burst when the pressure in the autoclave exceeds a predetermined limit, releasing excess pressure and preventing vessel rupture.

Temperature Control Devices

Temperature control devices monitor and control the temperature of the autoclave to prevent overheating or underheating. These devices include:

Temperature sensors: These sensors monitor the temperature of the autoclave and send signals to the control system to adjust the temperature as needed.

Thermostats: These devices control the temperature of the autoclave by regulating the flow of heat to the vessel.

Interlock Devices

Interlock devices prevent the autoclave from operating under certain conditions, such as when the door is not properly closed or when the pressure is not within a safe range. These devices include:

Door interlocks: These devices prevent the autoclave from operating when the door is not properly closed, preventing personnel from being exposed to high pressures and temperatures.

Pressure interlocks: These devices prevent the autoclave from operating when the pressure is not within a safe range, preventing overpressure or underpressure situations.

What is the purpose of a pressure relief valve on a cylindrical horizontal autoclave?

+The purpose of a pressure relief valve on a cylindrical horizontal autoclave is to release excess pressure in the event of an overpressure situation, preventing vessel rupture and ensuring safe operation.

How often should safety devices on a cylindrical horizontal autoclave be inspected and maintained?

+Safety devices on a cylindrical horizontal autoclave should be inspected and maintained regularly, according to the manufacturer's instructions and guidelines. This may include daily, weekly, or monthly inspections, as well as annual or bi-annual maintenance.

In conclusion, safety devices are essential to ensure the safe operation of cylindrical horizontal autoclaves. By understanding the different types of safety devices and their functions, personnel can take steps to prevent accidents and ensure a safe working environment. Regular maintenance and inspection of safety devices are crucial to ensure their effectiveness and prevent accidents.