How Is Ethylene Made Into Ethylene Glycol?

Ethylene glycol is a vital chemical compound used in various industries, including antifreeze production, plastics manufacturing, and as a precursor to other chemicals. The process of making ethylene glycol from ethylene involves several steps, which are critical for producing this essential chemical. In this overview, we will delve into the specifics of how ethylene is converted into ethylene glycol, exploring the chemical reactions, process conditions, and the significance of this transformation.

Introduction to Ethylene and Ethylene Glycol

Ethylene, a simple hydrocarbon with the chemical formula C2H4, is one of the most widely produced petrochemicals globally. It serves as a building block for numerous chemicals, including ethylene glycol. Ethylene glycol, with the chemical formula C2H6O2, is characterized by its hydroxyl groups, which make it an excellent solvent and intermediate in the production of various materials. The conversion of ethylene to ethylene glycol is a complex process that requires specific conditions and catalysts to achieve high efficiency and yield.

The Chemical Reaction

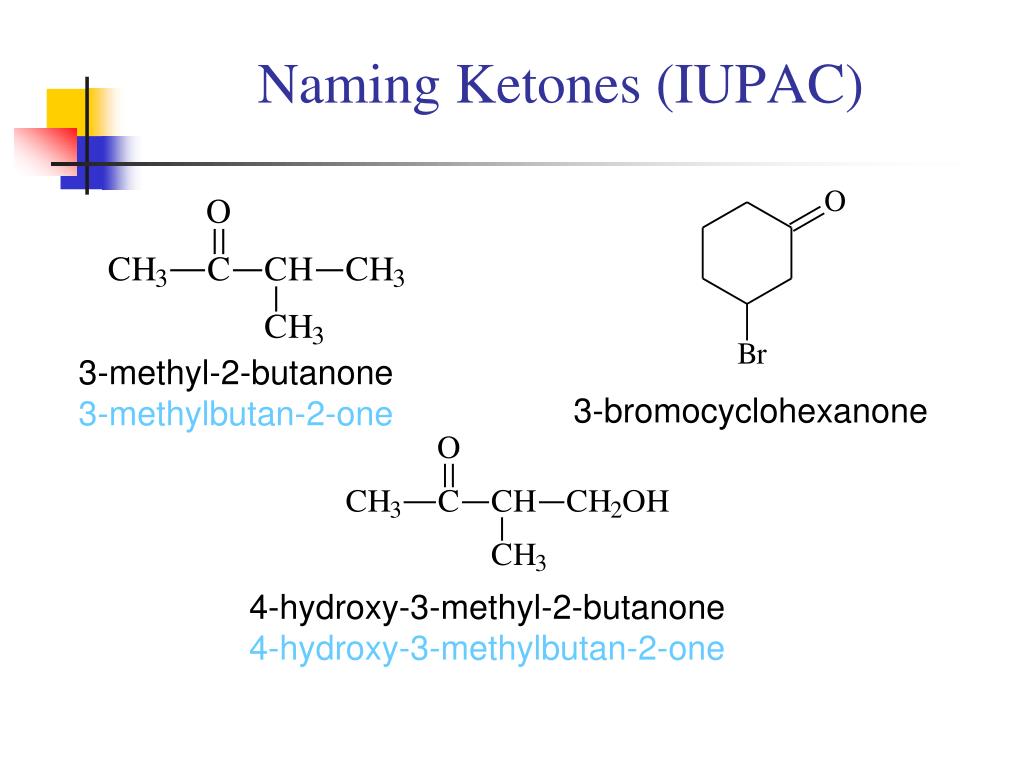

The production of ethylene glycol from ethylene involves the oxidation of ethylene to ethylene oxide, followed by the hydrolysis of ethylene oxide to ethylene glycol. This two-step process can be represented by the following chemical reactions:

1. Oxidation of Ethylene to Ethylene Oxide: C2H4 + O2 → C2H4O

2. Hydrolysis of Ethylene Oxide to Ethylene Glycol: C2H4O + H2O → C2H6O2

These reactions are facilitated by catalysts and require specific process conditions to optimize yield and minimize by-products. The oxidation step is typically carried out in the presence of a silver-based catalyst, while the hydrolysis step may involve an acid or base catalyst, depending on the process design.

| Process Step | Chemical Reaction | Catalyst |

|---|---|---|

| Oxidation | C2H4 + O2 → C2H4O | Silver-based |

| Hydrolysis | C2H4O + H2O → C2H6O2 | Acid or Base |

Industrial Production Processes

Industrial-scale production of ethylene glycol involves large, complex facilities designed to handle the high volumes of reactants and products. The process typically includes several stages beyond the basic chemical reactions, such as purification, distillation, and quality control measures to ensure the ethylene glycol meets the required specifications for its intended applications. Economies of scale play a significant role in the viability of these operations, as larger facilities can often achieve lower costs per unit of production.

Challenges and Developments

Despite its importance, the production of ethylene glycol faces several challenges, including environmental concerns related to the use of silver catalysts and the potential for by-product formation. Researchers and manufacturers are continually exploring new catalysts and process technologies that could improve efficiency, reduce costs, and minimize environmental impact. For instance, the development of more selective catalysts could reduce the formation of undesirable by-products, while alternative process routes might offer more sustainable pathways to ethylene glycol production.

One of the critical areas of focus is the direct oxidation of ethylene to ethylene glycol, potentially bypassing the ethylene oxide intermediate. This approach could simplify the process, reduce costs, and lower the environmental footprint of ethylene glycol production. However, achieving the necessary selectivity and yield under commercial conditions remains a significant technical challenge.

What are the primary applications of ethylene glycol?

+Ethylene glycol is primarily used as antifreeze in automotive applications, as a raw material in the production of polyethylene terephthalate (PET) plastics, and in various industrial processes as a solvent or intermediate.

How does the production of ethylene glycol impact the environment?

+The production of ethylene glycol can have environmental impacts, including the release of ethylene oxide, a known carcinogen, and other by-products. Additionally, the energy required for the process contributes to greenhouse gas emissions. Manufacturers are working to reduce these impacts through more efficient processes and the use of cleaner energy sources.

In conclusion, the conversion of ethylene to ethylene glycol is a complex, multi-step process that involves specific chemical reactions and catalysts. The significance of ethylene glycol in various industries, combined with the challenges and developments in its production, underscores the importance of continued research and innovation in this field. As the chemical industry evolves, the production of ethylene glycol will likely play a critical role in meeting the demands for sustainable, efficient, and environmentally responsible chemical manufacturing practices.